Bobbin winding is a crucial process in sewing machines that ensures smooth and uninterrupted sewing operations.

When the bobbin winds unevenly, it can lead to various complications, affecting the quality of stitches and overall sewing performance.

The reasons behind bobbin winding unevenly are essential for every sewing enthusiast to maintain their machines effectively. Uneven bobbin winding is a common sewing frustration, but fear not!

Here’s a dive into the culprits behind uneven bobbins and how to get them back on track.

Threading the Culprit

Improper Threading: Double-check your machine’s manual for the correct threading path. A rogue thread loop or missed guide can cause uneven tension.

Tension Troubles: Play with the thread tension knob. Too loose and the thread will bunch up, too tight and it can cause the bobbin to wind unevenly.

Machine Mischief

Misaligned Spindle: A bobbin spindle that’s slightly askew can cause the thread to wind off-center. This might require a trip to a sewing machine repair person.

Tension Disc: The tension disc regulates thread flow. If it’s misaligned, it can lead to bobbin winding unevenly. Some machines allow for tension disc adjustments, but consult your manual or a professional for this.

Bobbin Blues

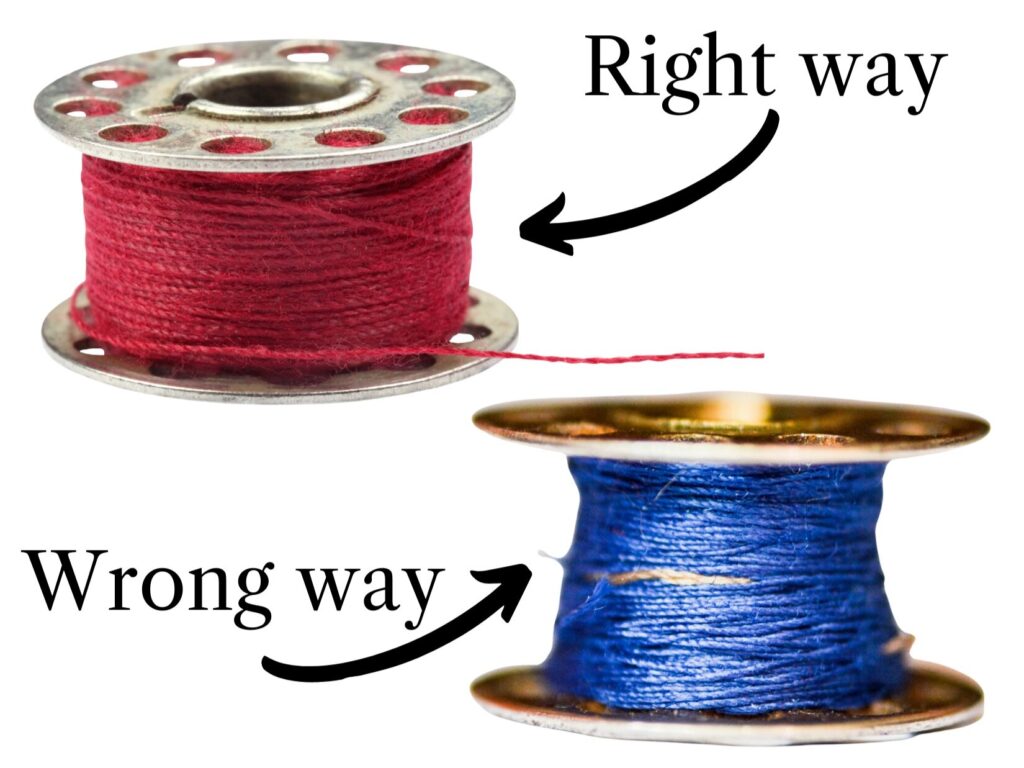

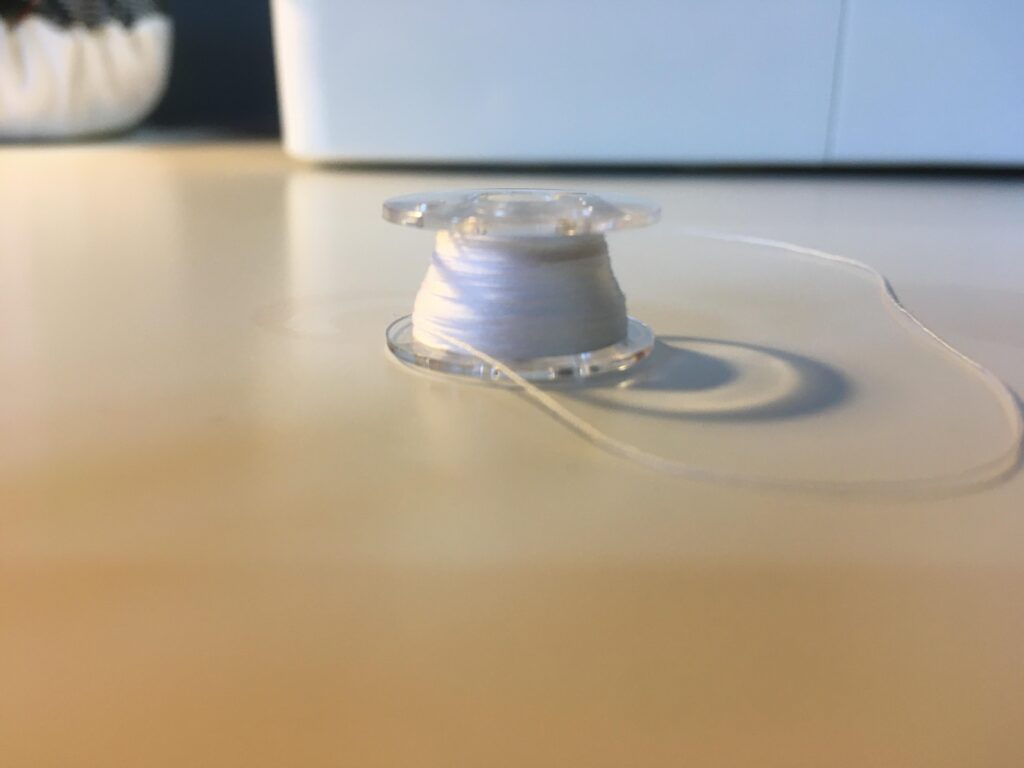

Warping: A warped bobbin is a recipe for disaster. Try using a different bobbin and see if the winding improves.

Shape Up! Ensure the thread is neatly placed on the bobbin notch. A lopsided start can lead to bobbin winding unevenly.

Bonus Tips

Thread Tamer: For thicker threads, a little help from your finger might be necessary. Gently guide the thread as it winds to prevent bunching.

Spool Shenanigans: Make sure the spool of thread is positioned correctly on the spool pin. An angled spool can cause uneven tension.

Bobbin Winding

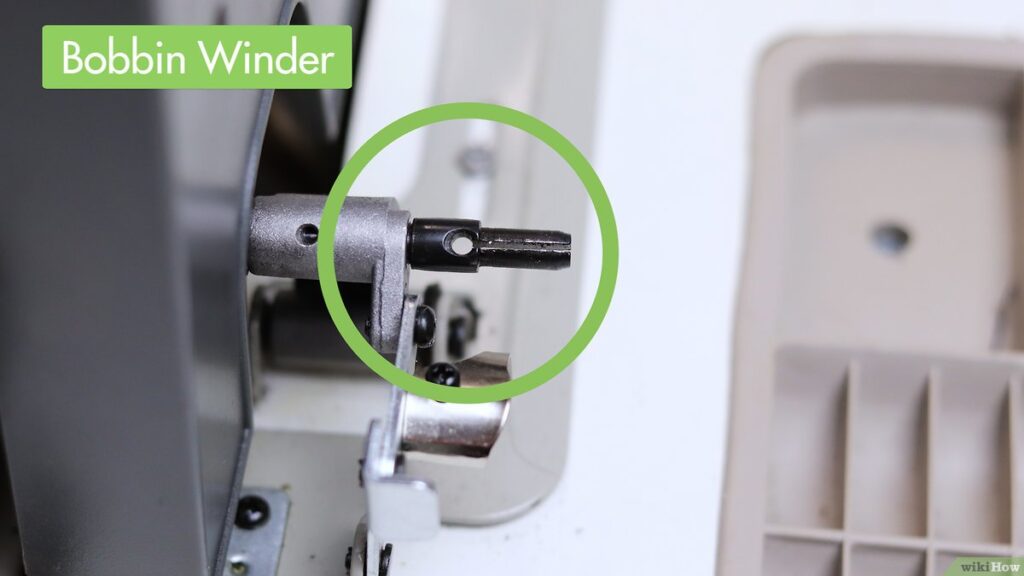

Bobbin winding is the process of neatly winding thread onto the bobbin, a small spool that holds the thread underneath the fabric during sewing. It involves several components, including the bobbin itself, the bobbin winder, and the tension discs.

Proper bobbin winding ensures that the sewing machine operates smoothly and produces high-quality stitches.

Causes of Uneven Bobbin Winding

Several factors can contribute to bobbin winding unevenly. Tension issues, such as incorrect bobbin tension or uneven tension on the sewing machine, can cause the thread to wind irregularly.

Using incompatible thread or poor-quality thread can result in bobbin winding unevenly.

Problems with the bobbin winding mechanism, such as a worn-out bobbin winder or a malfunctioning tension disc, can also lead to bobbin winding unevenly.

Effects of Uneven Bobbin Winding

Uneven bobbin winding can have detrimental effects on sewing quality. It can cause stitches to appear loose or uneven, leading to fabric bunching or puckering. If left unaddressed, bobbin winding unevenly can damage the sewing machine’s internal components, resulting in costly repairs.

Troubleshooting Uneven Bobbin Winding

To troubleshoot the bobbin winding unevenly, start by checking the tension settings on both the bobbin and the sewing machine. Adjust them as necessary to ensure proper tension.

Next, assess the thread quality, making sure it is compatible with the machine and in good condition.

Finally, inspect the bobbin winding mechanism for any signs of damage or malfunction, such as worn-out parts or loose connections.

Preventive Measures

To prevent uneven bobbin winding, it’s essential to perform regular maintenance on the, Handle thread properly, avoiding knots or tangles that can disrupt the winding process.

When installing a bobbin, make sure it is inserted correctly and securely to prevent slipping or jamming.

Seeking Professional Help

If issues with uneven bobbin winding persist despite troubleshooting efforts, it may be time to seek assistance from a professional sewing machine technician.

They have the expertise and tools to diagnose and repair more complex problems with the bobbin winding mechanism and other sewing machine components.

By following these tips and consulting your sewing machine’s manual, you should be well on your way to achieving perfectly wound bobbins and frustration-free sewing! If the problem persists, consider taking your machine to a qualified technician for further inspection.

FAQs

Why is my bobbin winding unevenly?

Uneven bobbin winding can be caused by tension issues, thread compatibility problems, or issues with the bobbin winding mechanism.

How do I fix uneven bobbin winding?

Start by adjusting tension settings, using high-quality thread, and inspecting the bobbin winding mechanism for damage or wear.

Can improper bobbin winding damage my sewing machine?

Yes, uneven bobbin winding can lead to stitching problems and potentially damage the internal components of the sewing machine if left unaddressed.

Is regular maintenance necessary to prevent uneven bobbin winding?

Yes, regular cleaning, lubrication, and inspection of the sewing machine are essential for preventing issues with bobbin winding.

When should I seek professional help for bobbin winding issues?

If troubleshooting efforts fail to resolve the problem, or if there are signs of damage to the sewing machine, it’s best to consult a professional technician.

Conclusion

In conclusion, why bobbin winding becomes uneven is essential for maintaining the performance of sewing machines. The causes of uneven winding and sewers can ensure smooth and consistent stitching results.

Regular maintenance, thread handling, and timely professional assistance are key to preventing and resolving issues with uneven bobbin winding.